Project Financing Assistance

An American Diversified Enterprises company

Projects Seeking Capital

Debt | Equity | Debt + Equity | Development Capital / Venture Capital | Investments in Funds of Funds

Please contact us for further information on one or more of the projects below

Projects Seeking Debt Financing

-- This project has a massive amount of available, low-cost power (up to 800 MW of renewable power and 500 million cubic meters of natural gas, enough for a 40 GW data center), with no risk of curtailment, as well as an unlimited supply of easily accessible 48-degree F. water for cooling. -- The project has a confirmed utility connection for an initial 85 MW of power and site control on a 50,000 square-foot building located next to a 110 kVa substation for Phase 1. -- The project can purchase an additional 200 adjacent acres and expand immediately, or in additional phases, to 200 MW or more at a PPA cost of less than 5-cents kWh. -- The project is initially being developed as a Bitcoin mining center (due to its low operating costs, it will be profitable at $70,000 BTC and above). -- Only the Bitcoin needed to pay for its operations and investor returns will be sold. -- The balance can be held tax-free. -- The facility will mine Bitcoin until after the next halving event in mid-2028, continuing operations until Bitcoin peaks, which has typically occurred about 9 months after a halving event. -- The Bitcoin which has accumulated and been held will be used as collateral for expansion into a data center and AI.

-- BargerTech has developed a highly-efficient, state-of-the-art waste-to-value processing system that turns environmental liabilities -- such as agriculture runoff, animal wastes, and organic municipal wastes -- into high-demand products. -- The modular, scalable TRiFi 7000™ system captures, processes, and converts any biomass/waste into three high-demand products: (1) 24×7 renewable, base load power, (2) clean, distilled water free from contaminants and pollutants, and (3) a revolutionary, nutrient-rich carbon-based NPK (nitrogen, phosphorus and potassium) fertilizer that promotes soil health and agricultural productivity. -- TRiFi 7000™ is capable of producing between 250 kilowatts (kWh) to 100 megawatts (MW) of renewable energy, with biomass processing capacities ranging from 10 tons/day to 1,000 tons/day, generating abundant clean water and natural fertilizers as its only by-products.

-- Rose Rock offers an unprecedented, turnkey solution for converting waste plastics into a wide variety of marketable products and building materials. -- Its fully automated cold extrusion processing system can convert ALL waste plastics, including those that currently are unrecyclable, contain contaminants, and have no market value. -- It also is adding a capability to process discarded wind turbine blades. -- Rose Rock produces a light, incredibly strong composite material that can be molded into an infinite number of shapes and is infinitely recyclable. -- The composite has a controlled density of 31-50 lb /cu ft, compressive strength up to 5,000 lb /psi (equal to concrete), tensile strength up to 2,200 psi (vs concrete’s 300-700 psi), no UV degradation, no effects from freezing and thawing, only a negligible thermal creep at 200º F, and radiation shielding equal to high-density concrete. -- Additional strength can be added with rebar, steel cable, and tensioned nylon cord. -- Rose Rock is seeking to expand the number of facilities it operates. -- It also can place a turnkey plastics-extrusion facility at any location at a cost of $5 million. -- This cost includes the building, granulators, materials silos and delivery system, chemical storage tanks, cold-extrusion production line, autoclave and water/air filtration system. -- Rose Rock will provide its proprietary chemicals to each facility and provide an on-site Rose Rock plant manager. -- A standard, single-plant package processes 39 tons of material in a single 10-hour shift, which equates to over 20 million pounds per year. -- Additional processing systems can be added in a modular array to increase capacity. -- The process uses unsorted, unwashed plastics with up to a 25% contaminant content. -- No sorting or cleaning is required. -- The waste plastics are granulated into a quarter-inch size, mixed with proprietary chemicals, and pumped through a large extruder at ambient temperature, which liquefies and compatibilizers all types of resins. -- The process converts the plastics’ polymers into monomers then back into polymers. -- Thus, the materials produced by Rose Rock are completely recyclable – indefinitely. -- The granules are extruded into a pool of water where the extrusion can be molded and cut to length with a wet saw. -- Contaminants are rendered inert through the chemical process. -- The extrusion is dried at ambient pressure and temperature inside an autoclave compartment which uses a vacuum to capture any potential off-gases, which are run through a water bath to remove any contaminants prior to release into the atmosphere. -- Once cured, the material exhibits no off-gassing or leaching. -- Because the extrusion still is malleable during its emersion in the water bath, it can be formed into multiple shapes and thicknesses, giving the material endless applications in a multitude of industries -- No other waste plastic processing system has these capabilities. -- Production costs for the material are extremely low, as low as 10% of the production costs for competing materials. -- Rose Rock’s “proof of concept facility,” which is still in operation, was operated for three years to prove out and refine its technology, producing products on a small commercial scale, including pallets, fence posts, pier pilings, parking stops, railroad ties, pavers, dimensional lumber, and products produced and sold on a custom-order basis. -- Rose Rock operates a commercial-scale facility in southern Indiana that is producing an ever-widening range of products that are sold through sale purchase agreements with building material suppliers.

-- ZOT Solutions is acquiring the intellectual property, restoring the customer base, and resuming fabrication of a highly efficient third-generation waste tire shedder and granulator. -- ZOT has a unique combination of machine and method. -- The C&B Machine, rebranded as the “ZOT Mill,” creates ultra soft rubber material in multiple sizes, at room temperature, in a single pass, with zero emissions from discarded commercial truck and heavy-duty equipment tires. -- The patent for the first generation model was issued on December 20, 2005. -- Development of the 3rd generation has been completed. -- ZOT will be applying to reopen the patent since there are significant advances to the original filing. -- The first two third generation ZOT Mills are complete and in operation. -- ZOT has the materials and orders in hand to build eight more 3rd generation units. -- A single ZOT Mill processes 1.5 tons of 3/4-inch shred rubber per hour. -- A ZOT Mill can produce multiple-sized material: ** ranging from 5/8-inch (for use as mulch, playing fields, horse arenas, and supplemental construction, such as a concrete additive), ** to 5-10-20 mesh (for a variety of rubber products such as general purpose mats, running tracks, ballistic mats, and injection molded products, ** to 200 mesh (high quality additive for sealants, paints, inks, and electronics). -- Manufacturers of rubber products are very specific about the quality of the recycled material they will accept. -- Several of the unique characteristics of ZOT Mill rubber products are: solvent tolerant for long-term storage, ultra-soft, lower bounce coefficient (desired by rubber manufacturers), and no cross contamination from car and light truck tires. -- A ZOT Mill also can shred cardboard, paper, and various types of bark. -- A ZOT Mill requires less maintenance, fewer repairs and part replacements, and retails and operates at half the cost of competitive waste tire shredders. -- ZOT Solutions manufacturing is based in Dover, Ohio. -- It intends to roll out rubber production plants on a quarterly basis to form a network across the U.S., with property negotiations currently underway in Dover, Ohio; Baltimore, Maryland; Lake City, Florida; Chicago, Illinois; Port Arthur, Texas; Boise, Idaho; and Paso Robles, California.

-- New Planet Energy (NPE) proposes to construct and operate a modern, reliable waste processing facility in St. Louis with a significant value proposition: ** The facility will recover as much as 80% of the waste material disposed of by St. Louis residents, using the waste to produce valuable commodities rather than sending it to a landfill. ** Recyclables will be extracted for producing new products. ** The remaining waste will be converted into a high-energy, low-emission fuel product that will power industrial plants. -- The fuel product, “New Planet Fuel,” is a “solid recovered fuel (SRF)” that is a U.S. EPA-approved fossil fuel replacement with a 10,000 BTU energy content per pound, compared with 8,100 to 13,000 BTU per pound for coal, and 9.7 cubic feet of natural gas. -- New Planet Fuel can be engineered to a range of specifications for size, moisture, and energy content to meet customer requirements. -- New Planet Fuel is less expensive on a pound for pound and BTU to BTU basis than both coal and natural gas. -- It also has significantly fewer emissions of CO2 , hazardous air pollutants, and heavy metals than coal and natural gas. -- Products similar to New Planet Fuel are helping European cement producers achieve a 40% fuel substitution rate, significantly reducing negative impacts on the environment. -- NPE offers municipalities multiple benefits, including: ** a much-needed solution to the traditional methods of trash disposal and recycling by providing all residents the opportunity to participate in recycling and diverting as much as 80% of waste from landfills, extending the life of landfills and using valuable commodities currently being thrown away. ** the opportunity to reduce the truck traffic, wear on roads, and number of trips for residential and commercial waste pickup, since recyclables can be disposed of in a single bin, without the need for separation and a separate pick up. ** one-stop waste processing and recycling, with a single, combined tipping fee for waste disposal and recycling, compared with competitors that charge a lower fee for landfill-only disposal (with all collected recyclables disposed in the landfill), but charge a much higher fee on a ton-by-ton basis for processing recyclables. ** the ability to achieve a Zero Waste Goal with cleaner air and improved health conditions for residents.

Projects Seeking Debt + Equity

Pending

Projects Seeking Equity Investments

-- VTV Energy intends to build six data centers by the end of 2031 with over 2 GW of power. -- Data center power will be provided by solar, battery energy storage systems (BESS), natural gas, and nuclear small modular reactors (SMRs). -- VTV Energy has site control of 947 acres in the Florida Panhandle under a lease purchase option. -- It has the option to gain site control over an additional contiguous 1,500 acres. -- Utility interconnection and load capacity applications are being prepared for filing. -- EPC, generator developer, and technology partners have been engaged. -- Applications for federal, state, and local permits are being prepared for filing. -- $8 million in seed round funding is being sought, with a pre-money valuation of $50 million and post-money valuation of $58 million with 13.79% equity. -- The project timeline is as follows: ** 2026: Seed capital deployment for: (1) site surveys (geotechnical, environmental, boundary, civil, etc.) (2) utility load service and interconnection filings, engineering kick off (natural gas, pre-FEED, solar/BESS design, data center layout) (3) legal retainers (permitting counsel, SPV creation, contracts) (4) hiring key team members (VP sales, director of energy, operations manager, accountant) (5) early financial modeling, grant preparation, preparation for U.S. Department of Energy Loan Program Office submission for $8 billion in financing ** 2027: Development + early construction ** 2028: Natural gas plant commissioning + Data center & solar farm/BESS construction + nuclear integration ** 2029: Two data centers online (off-grid power) ** 2030: Four data centers online + expanded power ** 2031: Six data centers online + grid upgrade complete

Projects Seeking Development Capital / Venture Capital

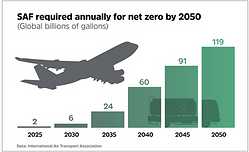

-- Blue Biofuels has developed a unique, patented cellulose-to-sugar (CTS) process that uses a mechanical-chemical system to convert virtually any cellulosic material into biofuels and sustainable aviation fuels. -- The CTS process can produce biofuel from abundant, low-cost plant-based materials faster and more efficiently than traditional ethanol production methods. -- Hardwoods, grasses, specialty plants, residential yard clippings, and agricultural and commercial wastes have been successfully converted into biofuel through the CTS process without retooling or alternating catalysts. ** This is done by first shredding the biomass to reduce its size ** The shredded biomass is then combined with a low-cost, recyclable catalyst. ** Next, the product goes through the CTS Reactor, where the cellulose is chemically and mechanically broken down. ** Further processing leads to sugars that can be fermented into ethanol. ** Unblended, the ethanol is completely biodegradable. ** The ethanol can be converted into sustainable aviation fuel using the alcohol-to-jet process developed by Blue Biofuel’s joint-venture partner Vertimass or further distilled to reduce its water content and sold as cellulosic ethanol. ** This leaves behind a high purity, chemically unmodified lignin as a byproduct, which is a natural polymer that can be used in high-value products like carbon fibers, bioplastics, and advanced resins, making specialty chemicals, purifying water, or as a clean-burning fuel replacement for coal. -- Unlike first generation biofuels, such as biofuels produced from corn and soy, cellulosic feedstocks can utilize agricultural, forest, and landscaping residuals and wastes, and can be grown on marginal cropland, producing more energy than the amount required to grow and harvest. -- Blue Biofuels is working with agricultural landowners in Florida to establish king grass plantations in close proximity to its Polk County biofuel production site to bring lands that have been impacted by hurricanes and citrus greening back into production. -- King grass is a non-invasive energy crop that requires relatively low input, grows well on marginal and previously cultivated land, reaches heights of 12-15 within just a few months, can be harvested multiple times per year, and only needs to be replanted once every seven years. -- An acre of king grass, harvested three times per year, will produce 3,000 gallons of biofuel compared with roughly 600 gallons per acre for corn. -- Blue Biofuels has applied for a U.S. Department of Agriculture Section 9003 Biorefinery, Renewable Chemical, and Biobased Products Manufacturing Assistance Loan Guarantee. -- Blue Biofuels is seeking a lender of record to participate in a public-private partnership with USDA for the loan guarantee as well as $3 million in development capital to expand its pilot plant into a fully integrated demonstration unit (IDU) and operate the IDU for 120 days to meet the USDA’s IDU requirement and technical due diligence.

-- Vertimass LLC holds a worldwide exclusive license for a novel catalyst technology invented at the U.S. Department of Energy’s Oak Ridge National Laboratory. -- Vertimass has continued to build on the technology, adding nine additional patents with additional patents pending. -- The technology is a one-step, single-reactor process that can convert alcohols (methanol, ethanol, butanols) derived from a wide range of biomass feedstocks, into renewable transportation fuels, chemicals, and liquid gases that are compatible with existing fuels and chemical infrastructures. -- The technology also offers the producers of ethanol and synthetic aviation fuels (SAF) a means of increasing their market share and, in turn, substantially expanding the use of sustainable fuels and chemicals: ** The SAF produced through other processes typically lacks aromatics and cyclo-alkanes, two components that are found in conventional jet fuel and are produced by the Vertimass technology. ** These components are critical for swellings seals to prevent leaks, providing energy density, aiding lubrication, and improving cold-weather operability. ** While synthetic aviation fuels (SAF) have the potential to reduce greenhouse gas emissions by up to 94%, as well as increasing thrust by as much as 17%, boosting range by 10%, and improving engine performance compared to conventional jet fuels -- depending upon the feedstocks and processes used to produce them -- their lack of these components means they must be mixed with conventional jet fuel, often in a 50/50 mix. ** Vertimass offers other SAF producers the ability to blend these components with their fuels, greatly reducing or eliminating the need to mix their fuels with conventional jet fuel, thus expanding the utility and use of SAF. ** Vertimass also can open up new markets for ethanol producers. ** Because most of the ethanol in the United States is limited to 10% blends with gasoline, current ethanol production has virtually saturated that market. ** Ethanol producers will be able to bolt on a Vertimass addition with very low capital and operating costs to use their existing facilities to expand into new liquid fuels and chemicals markets with the potential to: ++ increase corn grind and feedstock feed rates for existing processes ++ reduce energy and water use for ethanol production and ++ build new facilities that use cellulosic biomass -- Vertimass will be using a U.S. Department of Agriculture Section 9003 Biorefinery, Renewable Chemical, and Biobased Products Manufacturing Assistance loan guarantee to build its first commercial-scale facility in Polk County, Florida. -- It plans to widely license its technologies once the Polk County production facility is in operation.

-- Erg Bio was founded on a simple idea: the world’s waste can become one of its most valuable resources -- According to the 2023 U.S. Department of Energy “Billion-Ton Report”: ** 1.5 billion tons of biomass – enough to meet a significant portion of U.S. energy needs and ensure U.S. energy independence and dominance – go to waste in the U.S. each year. ** Unused agricultural waste residues, which could be converted into fuels and chemicals and provide additional income for farmers, represent $100 billion in lost value each year. -- Erg Bio uses a proprietary low-temperature solvent and bioprocessing technology to convert non-food biomass into fermentable sugars, high-value intermediates, and drop-in fuels. -- Erg Bio’s ASPIRETM technology is designed for reliability, scalability, and seamless integration with existing industrial supply chains. -- It works on over 40 agriculture residues, forest/woody waste, and municipal solid waste as well as dedicate energy crops, with the ability to switch back and forth between feedstocks and even use mixtures of different feedstocks. -- Erg Bio’s ASPIRETM technology offers the opportunity to create new revenue streams for feedstock suppliers, vitalize rural areas through the construction and operation of biorefineries that can inject as much as $100 million per year into local economies, shield major manufacturers from global market disruptions, and expand export markets for fuels and materials. -- Erg Bio has worked with the Department of Energy to scale up and validate its technology and is working with the Department of Defense to use its technology to produce critical materials for defense and rocket fuel and the Department of Agriculture to finance its first commercial-scale facility in Louisiana through the USDA’s Section 9003 Biorefinery, Renewable Chemicals & Biobased Products Manufacturing Assistance loan guarantee program. -- Erg Bio also is working with a beauty ingredients partner, chemical giant, and tire company giant on other products that can be produced with its ASPIRETM technology.

-- FrissOn Capital has access to more than 500 startups in a sector that is being disrupted with no specialized investors or support systems. -- It is raising the remaining $10 million for a $20 million fund of funds, targeting 40+ startups, projected to generate a 30-40% IRR while addressing unmet healthcare needs, global health challenges, and driving the next wave of health innovation.

Please contact us for further information on one or more of the projects above